Automated Micro Welding and Machining

of Multi-Conductor Wires

|

|

|

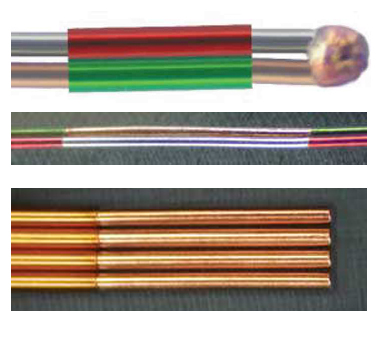

In 1985, SSDI developed itís first fully automated micro-wire assembly systems. SSDIís systems produce a wide range of micro-wire products for various industries that require stringent standards including, but not limited to the Medical and Computer disk drive industries ranging in sizes from .00023 inches to 26 gauge wires in single and multi-conductor configurations. These proprietary automated processes enable SSDI to reproduce consistent micro-wire assemblies of the highest quality standards while easily obtaining statistical Cpk values in excess of three on critical dimensional characteristics. SSDI is also a low cost producer due to the high degree of automation incorporated into its systems while maintaining the quality demanded by these high-tech industries. |

|

| SSDI designed and built equipment incorporates the latest Excimer and Yag Laser Technology. In the medical industry, SSDI produces a variety of conductor leads in a large number of configurations. These assemblies are used in a wide range of applications like thermocouples in bi, tri and quadfilar applications. SSDI can remove insulation with its Excimer systems in various lengths and widths to facilitate the industry's complex demands for conductor uses. |

|

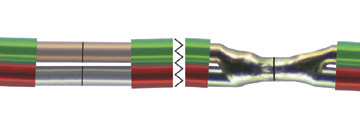

| In addition, by utilizing the latest Yag lasers, SSDI consistently produces welds in various wire applications of ferrous and non-ferrous materials. These welds can be provided in individual and reel-to-reel formats. Through utilization of the reel-to-reel configuration of the Weld and Strip operations SSDI can re-spool the wire in one continuous length. This allows the customer to remove from the spool as needed and simply cut in the center of the weld and strip locations to produce two finished assemblies in one single operation. |

|

| This unique process passes on a large cost savings to our customers through a great reduction in the cost of manufacturing, materials and handling. SSDIís individual micro-wire manufacturing format incorporates the same high quality standards as the reel-to-reel except SSDI will cut to length and package the micro-wire leads to our customerís requirements. |

Click

here to view SSDI's precision capabilities:

|